How Data-Driven Decisions Boost the Future of Industrial Manufacturing

The industrial manufacturing industry produces unprecedented amounts of data, which is increasing at an exponential rate. Worldwide data is expected to hit 175 zettabytes (ZB) by 2025, and 90 ZB of this data will be from IoT devices. The process of digitization across manufacturing has created new sources of data as manufacturers have begun incorporating artificial intelligence (AI), machine learning, and the increasing use of robotics. As this data increases, so does the potential of the business to shorten cycles, create new business models, and drive better revenue opportunities.

Yet harnessing the correct data, turning that into manufacturing savvy, and achieving smart decisions from it are complex and overwhelming tasks. In fact, according to a recent survey, two-thirds of manufacturing leaders indicated they had not maximized the potential benefits of analytics for operational insights and decision making.

Managing this increasing amount of data can wreak havoc on your financial teams. No longer is finance just expected to report the numbers: Modern finance teams are now expected to be the go-to-people who provide data-driven strategic insights to help across the organization, as well as meet the same deadlines as before, or even faster. In manufacturing, with the influx of new data sources and the increase in data volumes, staying on top of all of this data poses a tangible challenge.

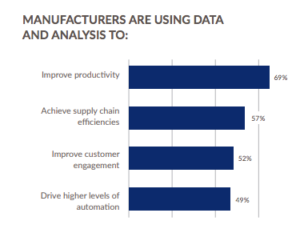

As an example, one high tech manufacturer revealed it had saved $3 million by analyzing the data produced by its equipment to predict quality issues, but had to process 5 terabytes of machine data every single hour to get that result. Today, manufacturers depend on data for analysis to improve productivity, drive supply chain efficiencies, increase customer engagement, and help increase greater levels of automation.

Source: “Manufacturing’s Digital Transformation: Is Your Company Leading the Way or Falling Behind?”

Mind the Gap

Are you challenged by the ability to track and analyze data specific to each department within your organization? Can you correlate data across all departments for informed decision-making? You may find it difficult enough to manage data in finance, but what about including information from procurement or your supply chain on suppliers, raw materials, pricing, and terms? Or reporting across multiple manufacturing units?

As you evaluate costs in production and track costs on process, labor, and machine data, are you confident you have all the information you need to quickly assess where teams can cut costs or optimize value? Considering ongoing fluctuations in sales orders, inventory, shipping, and distribution data, your reporting can quickly become complex if it is connected to other systems that are constantly experiencing change, which can lead to bottlenecks or gaps in your data.

KPIs: Establishing a Baseline

Finance is uniquely positioned to untangle all that data and find the gems of insights that will help the business improve profitability. But how can they do this? In order for data analysis to make a true impact on business, the first step is to determine the correct key performance indicators (KPIs). What’s the difference between a KPI and a Metric?

Here’s a quick rundown of some of the most important KPIs for data-focused manufacturing companies:

- Manufacturing Cycle Time: The length of time from start of production to a finished good. By analyzing this metric, finance can help teams speed processes and improve costs.

- Throughput and Overall Equipment Effectiveness: Measuring how much is produced per line by time. This metric helps finance determine overall effectiveness of equipment and percentage of improvement in production time.

- Capacity Utilization: Measures how much of available capacity is actually being used on the production line. The higher the better. Buildings and equipment are expensive assets and the goal is to maximize their use.

- Inventory Turns: Measuring amount of inventory maintained per manufacturing step. Keeping inventories to a minimum can help free up cash and enable manufacturers to respond to changing customer needs much more efficiently with better delivery times.

- First Pass Yield: The percentage of products manufactured correctly and to spec the first time through the process. Increasing this number reduces scrap and rework costs.

- Failed Audits: Measuring the number of failed audits prior to a shipment going out. This helps finance manage costing on product rework, scrap, and delays. The goal for this KPI should be 0 failed audits, and if it’s not, a root cause analysis will need to be performed.

With the proper KPIs in place, finance teams can begin the process of gathering the right data to analyze where improvements in costs, efficiencies, and processes can take place.

Organizing across Data Siloes

Your manufacturing business is heads-down on production. Your company’s inventory levels, raw materials availability, machinery, and labor are the primary focus. Data from manufacturing processes is commonly captured in the organization’s ERP system. However, once data is in the ERP, finance teams still need to understand and correlate data across materials, quantities, sources, and production cycles—often stored in siloed modules—in order to reconcile the financial aspects of that data with other relevant supplier and inventory data. Finance must be able to perform reconciliations and create consolidated reporting across multiple divisions and remote operations, adding another layer of siloed data complexity. Multiply this by the number of other departments or business units that have data that finance needs, and you can begin to see the challenges facing your finance team.

This orchestration and coordination of data siloes can cause delays if finance is unable to either access or process the data. It may cause inaccuracies if the data is manually consolidated into reports. And it may be difficult to research discrepancies or issues if the data has been separated from its original source. In larger manufacturing operations, data like this is often collected and integrated into a data warehouse under IT’s control. In this scenario, IT is often responsible for creating and managing reporting for finance, but has difficulty keeping the data refreshed in a timely way for finance’s needs. Once the data is in a data warehouse, investigating data issues down to where they originated is nearly impossible.

Empowering Decision-Making with Purpose-Built Analytics and Reporting Tools

Finance teams and accountants are crucial in helping manufacturers understand new value streams and opportunities from their data. With the right analytics and reporting tools in place, finance teams in manufacturing can help identify quality improvement, reduce production line failures, improve manufacturing flow for faster cycles, and optimize their supply chain for better predictability and cost.

With analytics and reporting tools that are purpose-built for finance, manufacturers have a leg up on the reporting they need to drive predictions, profitability, and return on investment. With reporting that can access ERP data directly, they can quickly analyze pricing to enable them to reasonably charge more for products. Risks related to product liabilities can be more easily identified and avoided. Increasing amounts of data can be quickly captured and incorporated into an informed decision-making process. Your finance team needs the ability to do this research, analysis and reporting on its own through the help of a self-service reporting tool, so that they can quickly address issues and make sure no revenue opportunity is left on the table.

The industrial manufacturing company of the future will be powered by data analytics. The companies that thrive—rather than simply survive—will be those that find the best ways to harness their data to improve operational and business performance. Self-service analytics and reporting solutions prebuilt for finance that integrate across all your data help finance teams in manufacturing businesses make those key data-driven decisions that will improve their processes and drive ongoing revenue.

Learn more about manufacturing cost accounting gaps and how the right solutions can help you close them. View our Cost Accounting Gaps infographic here.